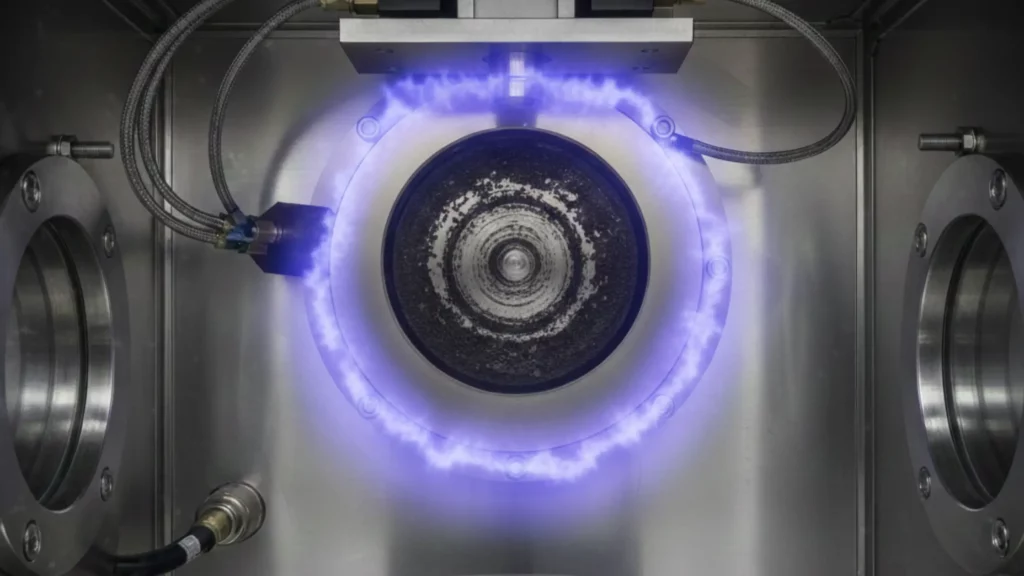

Thin Film Lithium Niobate Deposition via Magnetron Sputtering

Thin Film Lithium Niobate (TFLN) has become one of the most sought-after materials in modern photonics and integrated optoelectronics. With applications in telecommunications, quantum computing, photonic integrated circuits (PICs), and high-frequency electro‑optic modulators, TFLN is increasingly recognised as a cornerstone material for next‑generation optical technologies. [1],[2] Among available physical vapour deposition (PVD) techniques, magnetron sputtering […]

Thin Film Lithium Niobate Deposition via Magnetron Sputtering Read More »