By exploiting the plasmonic properties of nanomaterials, surface-enhanced Raman offers a dramatic increase in sensitivity compared to conventional Raman spectroscopy, enabling the detection of analytes down to parts-per-billion (ppb) levels.

We’ve used our state-of-the-art nanoparticle deposition technology to develop high-performance, low-cost substrates for surface-enhanced Raman, enabling laboratories of all sizes to achieve cheap, versatile and ultrasensitive analyte detection.

Surface-enhanced Raman fundamentals

When light interacts with matter, a tiny fraction of the light waves will scatter inelastically: this means that a light wave (photon) loses some of its energy to the chemical bonds of the molecule it interacts with before being re-emitted in a different direction. This process is known as Raman scattering.1

The amount of energy donated by a photon to a molecule during Raman scattering depends on the precise nature of the molecule’s chemical bonds. The loss in photon energy is detectable as a shift in the frequency of the emitted photon compared to the absorbed photon, which corresponds to a specific vibrational mode of the molecule it interacted with.

Raman spectroscopy exploits this phenomenon to analyse a sample’s chemical makeup. By probing a sample with a monochromatic light source and measuring the frequency shifts that occur due to Raman scattering, it’s possible to identify the chemical bonds – and therefore the specific molecules –present in the sample.

In 1973, researchers at the University of Southampton made a landmark discovery while observing the Raman spectrum of pyridine: they found that allowing a sample to adsorb to certain surfaces (in their case, a roughened silver electrode) could significantly enhance the intensity of Raman scattering and thus the sensitivity of Raman spectroscopy.2 This formed the basis of surface-enhanced Raman spectroscopy.

Today, surface-enhanced Raman is achieved through nanotextured surfaces that exhibit plasmon resonance, such as gold or silver nanoparticles. Surface-enhanced Raman spectroscopy is known to be capable of providing an enhancement factor of up to 1012 (1,000,000,000,000) over conventional Raman spectroscopy, making it one of the most sensitive analytical spectroscopy techniques in the world.3

Applications and benefits of surface-enhanced Raman

The primary advantages of surface-enhanced Raman are its sensitivity and selectivity, enabling the detection of less-than-monolayer coverage of an analyte on a surface, even in a complex mixture.4 Surface-enhanced Raman is non-invasive and non-destructive, and relatively low sensitivity to water means that surface-enhanced Raman is suitable for all in-situ and in-vitro applications for biological samples. Surface-enhanced Raman also works under a range of temperature and pressure conditions; and typically returns results in a matter of seconds (or, in some cases, even faster).5

The power and flexibility of surface-enhanced Raman make it suited to extensive surface/interface chemistry, biology, catalysis, food science, nanotechnology, environment monitoring and pharmaceuticals.6 However, despite the clear advantages of surface-enhanced Raman, the technique has long remained underutilised due to the high cost of suitable substrates and poor measurement reproducibility

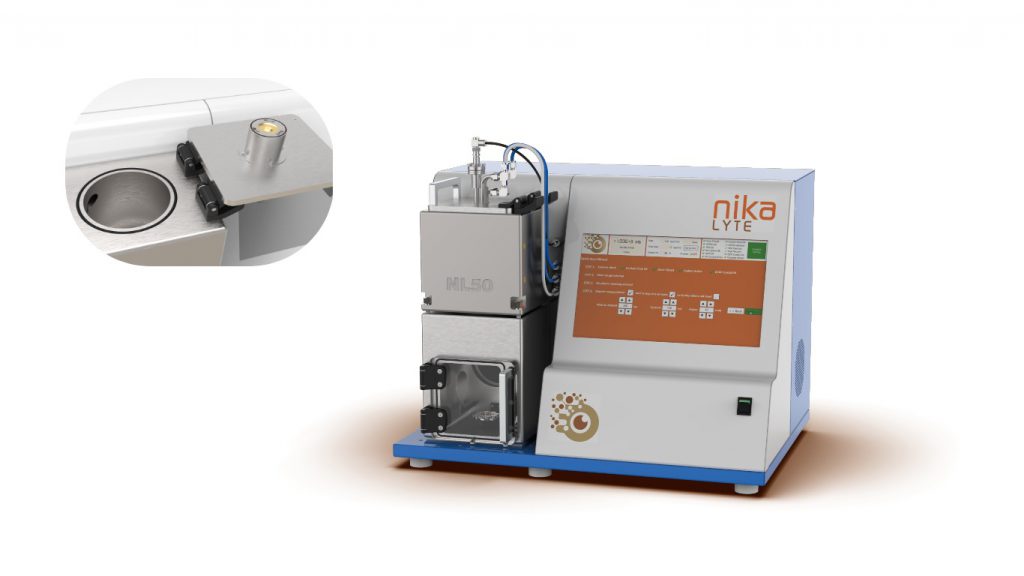

Nikalyte has set out to solve the affordability problem in surface-enhanced Raman spectroscopy. Using our signature nanoparticle deposition system, we have developed affordable and versatile gold nanoparticle substrates to make surface-enhanced Raman affordable and practical for any lab. Unlike chemically-synthesized nanoparticles, our vacuum nanoparticles are ultra-pure and free from hydrocarbons or ligands. Hence our ‘naked’ gold nanoparticle SERS substrate offer very high Raman signal to noise and enhanced detection sensitivity.

To learn more about our surface-enhanced capabilities, get in touch with Nikalyte today.