In today’s race for faster, more efficient semiconductors and advanced electronic materials, true innovation begins at the atomic scale. Whether it’s next-generation optoelectronics, wide-bandgap power devices, or quantum materials, the performance of these technologies depends on the precision and purity of their thin-film layers. The RF (Radio Frequency) Atom Source has become a pivotal component in Molecular Beam Epitaxy (MBE), Pulsed Laser Deposition (PLD), and sputtering systems, enabling the controlled delivery of highly reactive neutral atoms for superior thin film deposition. By enhancing material quality and process efficiency, this technology offers researchers and innovators a strategic edge in the competitive landscape of semiconductor fabrication.

What is an RF Atom Source?

An RF atom source is a plasma-based device employed in Molecular Beam Epitaxy (MBE) systems to produce neutral, highly reactive atomic species from molecular gases such as nitrogen, oxygen, hydrogen, or argon. This technique is particularly valuable for materials that are otherwise challenging to evaporate or thermally dissociate using conventional sources.

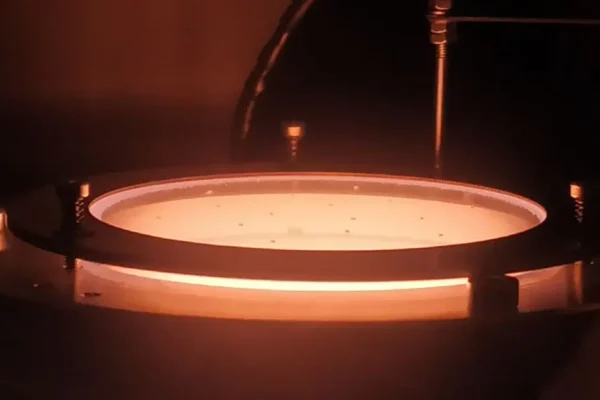

The core mechanism involves introducing a process gas into a discharge cavity, where an inductively coupled RF coil, typically operating at 13.56 MHz, generates an electromagnetic field. This field excites the gas, forming a plasma that breaks down the molecules into neutral atoms or radicals (e.g., N*, O*). While ions remain confined within the plasma, these neutral atoms exit through an aperture into the growth chamber.

Because these atoms are in a low-energy, yet highly reactive state, they play a critical role in the epitaxial growth of high-purity thin films. This includes compound semiconductors like GaN, AlN, InN, and various complex oxides such as SrTiO₃ and LaAlO₃. The enhanced reactivity of these atomic species allows for defect-free, stoichiometrically precise film deposition, essential in advanced electronic and optoelectronic applications.

Why Use RF Atom Sources for Nitrides and Oxides?

- Enabling the Growth of Challenging Materials: Traditional effusion cells don’t work well for elements like nitrogen or oxygen, which are gases at room temperature. RF plasma sources crack these gases into active atoms, enabling growth of III-Nitrides such as GaN, InGaN, and GaInNAs, essential for LEDs, laser diodes, and high-frequency electronics Similarly, atomic oxygen supports the fabrication of complex oxides including high-k dielectrics, transparent conducting oxides, wide-bandgap semiconductors, and high-temperature superconductors—materials crucial for advanced electronic, photonic, and energy devices.[1]

- Enhanced Film Quality through High Reactivity: The reactive atoms produced in the plasma have higher sticking coefficients and chemical activity, leading to smoother films, better stoichiometry, and fewer defects.[2]

- Precision Control for Tailored Growth: RF atom sources offer fine-tunable process parameters, including RF power, gas flow rate, and chamber pressure. This level of control allows researchers and engineers to precisely manage growth rates, doping concentrations, and film properties, ensuring optimal performance for a variety of applications.[3]

- Seamless Integration with Ultra-High Vacuum Systems: All-metal construction RF plasma sources integrate seamlessly with MBE systems, preserving the ultra-high vacuum needed for epitaxial layer-by-layer growth.

- Versatility in Doping and Cleaning Applications: In addition to film growth, atomic nitrogen and oxygen are widely used for dopant incorporation in III-V and II-VI semiconductors, particularly for thin-film solar cells and other photovoltaic structures. Atomic oxygen also serves as an effective in-situ cleaning agent, removing residual carbon from substrates to improve adhesion and surface quality.[4]

Applications of RF Atom Sources in Research and Industry

- LEDs and Laser Diodes : The growth of GaN and InGaN epitaxial layers using RF plasma sources is foundational to modern optoelectronics. These materials are essential for producing high-brightness LEDs, laser diodes, and solid-state lighting solutions. Plasma-assisted MBE enables smooth, defect-free films with superior light-emitting efficiency.[5]

- Power Electronics : RF-assisted MBE enables the deposition of AlGaN/GaN heterostructures, crucial for fabricating high electron mobility transistors (HEMTs). These devices are key components in RF amplifiers, electric vehicles, and 5G base stations, benefiting from the high breakdown voltage and thermal stability of nitride materials.[6]

- Quantum and Correlated Electron Devices: RF plasma sources allow for the atomic-scale fabrication of oxide interfaces such as LaAlO₃/SrTiO₃, which exhibit novel phenomena like 2D electron gases and superconductivity. These precision-grown interfaces are indispensable in quantum computing, spintronics, and emergent material studies.[7]

- Ferroelectric and Multiferroic Thin Films: The ability to fine-tune stoichiometry and layer structure using RF plasma is critical for synthesizing complex oxide heterostructures with ferroelectric, multiferroic, or piezoelectric properties. These materials find applications in non-volatile memory, sensors, and actuators.[8]

Conclusion

Integrating Nikalyte RF atom sources into your deposition system is a game changer for advancing the precision and quality of materials in semiconductors, optoelectronics, and quantum technologies. By enabling fine control over atomic species and thin-film growth, RF sources are key to unlocking the potential of next-generation devices. Whether you’re in a research lab or scaling up to production, selecting the right RF atom source—such as the NL-ATS30 with a compact 30 mm beam for R&D, or the NL-ATS60 with a larger 60 mm beam for pilot and production applications—could be the silent advantage that propels your project to success. With its CF63 flange system and CF100 flange options, these tools are designed for versatility and efficiency, offering enhanced material quality and streamlined scalability.

References:

- Mackenzie, J.D., Abbaschian, L., Abernathy, C.R. et al.Plasma characteristics and the growth of group III-nitrides by metalorganic molecular beam epitaxy. Electron. Mater. 26, 1266–1269 (1997). https://doi.org/10.1007/s11664-997-0067-y

- Piquette, E.C., Bridger, P.M., Bandić, Z.Z. et al. Growth of III-Nitrides by RF-Assisted Molecular Beam Epitaxy. MRS Online Proceedings Library 512, 387–392 (1998). https://doi.org/10.1557/PROC-512-387

- N. Günaydın, A. O. Çetinkaya, M. Torabfam, A. Tütüncüoğlu, C. I. Kayalan, M. K. Bayazıt, M. Yüce, and H. Kurt, Plasmonic group IVB transition metal nitrides: Fabrication methods and applications in biosensing, photovoltaics and photocatalysis, Adv. Colloid Interface Sci. 333, 103298 (2024). https://doi.org/10.1016/j.cis.2024.103298

- B. Nair and S. J. Dhoble, 3 – Semiconductor LEDs, in The Fundamentals and Applications of Light-Emitting Diodes, edited by G. B. Nair and S. J. Dhoble (Woodhead Publishing, 2021), pp. 61-86. ISBN 9780128196052. The Fundamentals and Applications of Light-Emitting Diodes | ScienceDirect

- Johnson, M. A. L., Yu, Z., Boney, C., Rowland, W. H., Hughes, W. C., Cook, J. W., Schetzina, J. F., El-Masry, N. A., Leonard, M. T., & Kong, H. S. (1997). Growth of GaN, InGaN, and AlGaN films and quantum well structures by molecular beam epitaxy. In Compound Semiconductors 1996, Proceedings of the Twenty-Third INT Symposium on Compound Semiconductors held in St Petersburg, Russia, 23–27 September 1996 (1st ed., p. 4). CRC Press. https://doi.org/10.1201/9781003063087

- -T. Kwak, S.-B. Chang, H.-J. Kim, K.-W. Jang, H. S. Yoon, S.-H. Lee, J.-W. Lim, and H.-S. Kim, Operational Improvement of AlGaN/GaN High Electron Mobility Transistor by an Inner Field-Plate Structure, Appl. Sci. 8(6), 974 (2018). https://doi.org/10.3390/app8060974

- Nanishi, Y., & Yamaguchi, T. (2022). Plasma-excited MBE—Proposal and achievements through R&D of compound semiconductor materials and devices. Japanese Journal of Applied Physics, 61(SA), SA0810. https://doi.org/10.35848/1347-4065/ac3d0c

- Y. Wang, W. Chen, B. Wang, and Y. Zheng, Ultrathin Ferroelectric Films: Growth, Characterization, Physics and Applications, Materials 7(9), 6377-6485 (2014). https://doi.org/10.3390/ma7096377