Image Description: Nikalyte’s Alloy Nanoparticle UHV (Ultra-High Vacuum) Deposition Source at the University of Oxford, with Peixi Cong and Leanne Jones (Postdoctoral Fellows).

Industry: Green Energy / Hydrogen Production / Nanomaterials

Challenge:

As global efforts ramp up towards decarbonization, efficient hydrogen production from water electrolysis becomes increasingly important. A major barrier to scaling up water electrolysis is the use of precious metals, such as platinum, iridium, and ruthenium, in electrocatalysts for the Oxygen Evolution Reaction (OER). These materials are not only costly but also scarce, making it imperative to explore more affordable alternatives that can perform efficiently while reducing the cost of hydrogen production.

The challenge is to develop high-entropy alloy (HEA) electrocatalysts that can provide the same or better performance than traditional precious-metal catalysts while being made from abundant, low-cost elements. The key goal is to ensure scalability, high efficiency, and longevity under operational conditions.

Solution:

This Materials Challenge Accelerator Programme (MCAP) project, a collaboration between University of Oxford, Diamond Light Source and Nikalyte Ltd, demonstrated the controllable deposition of high-entropy alloy nanoparticles for electrochemical hydrogen production. The selected alloys included ternary (Ni₀.₆Fe₀.₂Co₀.₂) and 5-element (NiFeCoMoAl, NiFeCoMoCr) compositions. These alloys are composed of more abundant, cost-effective elements compared to traditional precious-metal catalysts, and were designed with each element playing a unique role in the multi-step OER process.

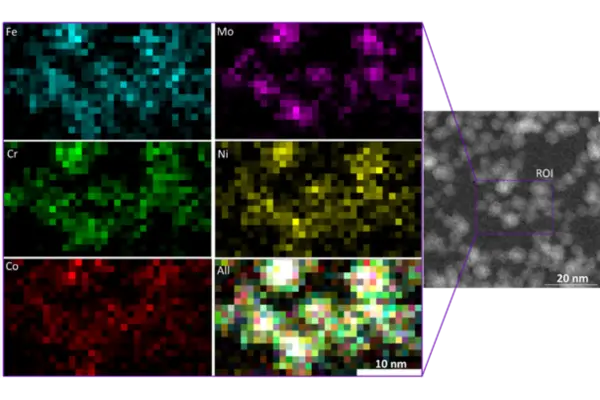

Image Description: EDS map of NiFeCoMoCr nanoparticles confirming formation of 5 element alloy composition.

Using Nikalyte’s nanoparticle deposition technology, the team successfully controlled the deposition of these alloys at the mg/cm² scale, achieving reproducible particle size distributions. Various characterization techniques were employed, including Transmission Electron Microscopy (TEM), X-ray Photoelectron Spectroscopy (XPS), and synchrotron-based XPS measurements at the Diamond Light Source.

This approach allows for a detailed understanding of the alloy composition, atomic structure, and its performance as an electrocatalyst in real-world applications, which is crucial for scaling up hydrogen production technologies.

Image Description: TEM (Transmission Electron Microscopy) image of NiFeCo nanoparticles, showcasing their fine structure and uniformity at the nanoscale. Image credit University of Oxford , Weatherup Group.

Results:

Through meticulous research and development, several key outcomes were achieved:

- Reproducibility and Scalability: The project demonstrated that the gas-phase synthesis of nanoparticle electrocatalysts could be controlled and scaled to the mg/cm² level, which is vital for real-world applications in electrolysis systems.

- Demonstration of Alloy Nanoparticle formation: The formation of multielement nanoparticles using the NL-DX3 triple target source was confirmed using EDS mapping carried out by Peixi Cong at University of Oxford.

- Characterization and Analysis: The alloys were extensively characterized using TEM, XPS, and synchrotron-based XPS at Diamond Light Source. These measurements revealed uniform distribution and consistent structural properties, which are essential for achieving high efficiency and longevity in electrochemical reactions.

- Electrochemical Testing: Although the full electrochemical testing was not concluded within the project timeframe, preliminary data indicate the potential of these high-entropy alloys to perform effectively as Ir based OER catalysts.

The work carried out in this project is aligned with the UK government’s ambition to scale up hydrogen production, with an investment of £100 million to develop 250 MW of electrolytic hydrogen by 2023, with a target of 5 GW by 2030.

Conclusion:

The high-entropy alloy catalysts developed during this project represent a promising alternative to traditional precious-metal-based catalysts. By focusing on more earth-abundant and cheaper elements, the project has the potential to significantly reduce the cost of hydrogen production, which is crucial for the UK’s net-zero goals.

This work provides a solid foundation for further research, including optimizing the alloy compositions and integrating them into electrolyser systems for industrial-scale hydrogen production. The project’s findings will also contribute to the growing body of knowledge necessary to meet the ambitious Paris Agreement targets and the UK’s legally binding 2050 net-zero emissions goal.

Note: Full details of the project and results are confidential, protected under an NDA.

Looking to develop efficient high-entropy alloy catalysts for your hydrogen production system?

Contact us today to learn more about how Nikalyte’s nanoparticle deposition technology can advance your electrochemical research and help scale up sustainable hydrogen production.