Spherical gold nanoparticles are advanced nanomaterials having diverse applications such as targeted drug delivery, radiotherapy, biological imaging, sensors, and chemical catalysis. Gold nanoparticles can be produced by either chemical methods such as aerosol-assisted chemical vapour deposition, hydro-thermal reduction, and microemulsion or by physical procedures such as plasma-assisted vacuum deposition, laser ablation, spray pyrolysis, and ion implantation.

This blog post describes how spherical gold nanoparticles are produced via the vacuum deposition method with a focus on NL50, a unique deposition tool developed by Nikalyte.

Vacuum deposition method

The vacuum deposition method is an advanced, top-down physical deposition technique to produce monodisperse and highly pure spherical gold nanoparticles. The starting base material is over 99.999% pure gold disc. The source material is first loaded into the chamber before the atmospheric gases are vented to create a clean, vacuum environment. The spherical gold nanoparticles are produced via magnetron sputtering in which the ions of energized gas (plasma) knock off individual atoms from the high-purity source material. These individual atoms adhere to each other to form small clusters that gradually join and form spherical gold nanoparticles. The detailed morphologies of spherical gold nanoparticles can be studied using high-resolution transmission electron microscopy. Spherical gold nanoparticles also possess the lowest cytotoxicity compared to nanorods and nanostars-shaped nanoparticles, making them most suitable for life sciences applications.

The size of spherical gold nanoparticles can be finetuned by controlling the process parameters such as the gas flow rate and the magnetron power. Upon generation, the spherical gold nanoparticles are extracted from the generation zone into the sample chamber and gets deposited onto the substrate surface. The final morphology of spherical gold nanoparticles depends on their size and the ratio between their surface and bulk energies. The gold nanoparticles smaller than 10 nm assume a spherical shape, and beyond 10 nm, they become icosahedral. The size of gold nanoparticles plays a crucial role in determining their optoelectronic properties. Gold nanoparticles below 30 nm appear red, while those larger than 30 nm appear blue. The high surface-area-to-volume ratio of spherical gold nanoparticles also enhances their detection sensitivity. The user, having complete process control over vacuum deposition process parameters in NL50, can thus easily tailor the nanoparticle size depending on the target application.

Advantages of vacuum-based method over chemical synthesis

The traditional methods of producing gold nanoparticles include a bottom-up chemical synthesis approach. The huge advantage of the vacuum deposition technique is that it produces exceptionally pure spherical gold nanoparticles that do not contain any hydrocarbons or ligands. In contrast, the chemically synthesized spherical gold nanoparticles contain hydrocarbons as impurities and form agglomerates in solution, i.e., they possess poor colloidal stability. Moreover, the interaction of ligands with solvent molecules in the reaction medium impacts the growth of nanoparticles. The chemical synthesis also uses toxic reduction agents that can prove hazardous due to undesirable product formation. Another drawback of chemical synthesis is that its process protocol is not easily controllable; factors like pH, concentration, and temperature must be closely followed to achieve desired monodisperse gold nanoparticles. Vacuum deposition of gold nanoparticles circumvents all these drawbacks.

The unique advantage offered by the vacuum deposition technique is its line-of-sight deposition that allows uniformly coating planar and textured substrates with spherical gold nanoparticles. The uniformly coated substrates make it possible to achieve an unprecedented ppb-level detection sensitivity. These substrates are used in surface-enhanced Raman sensors (SERS).

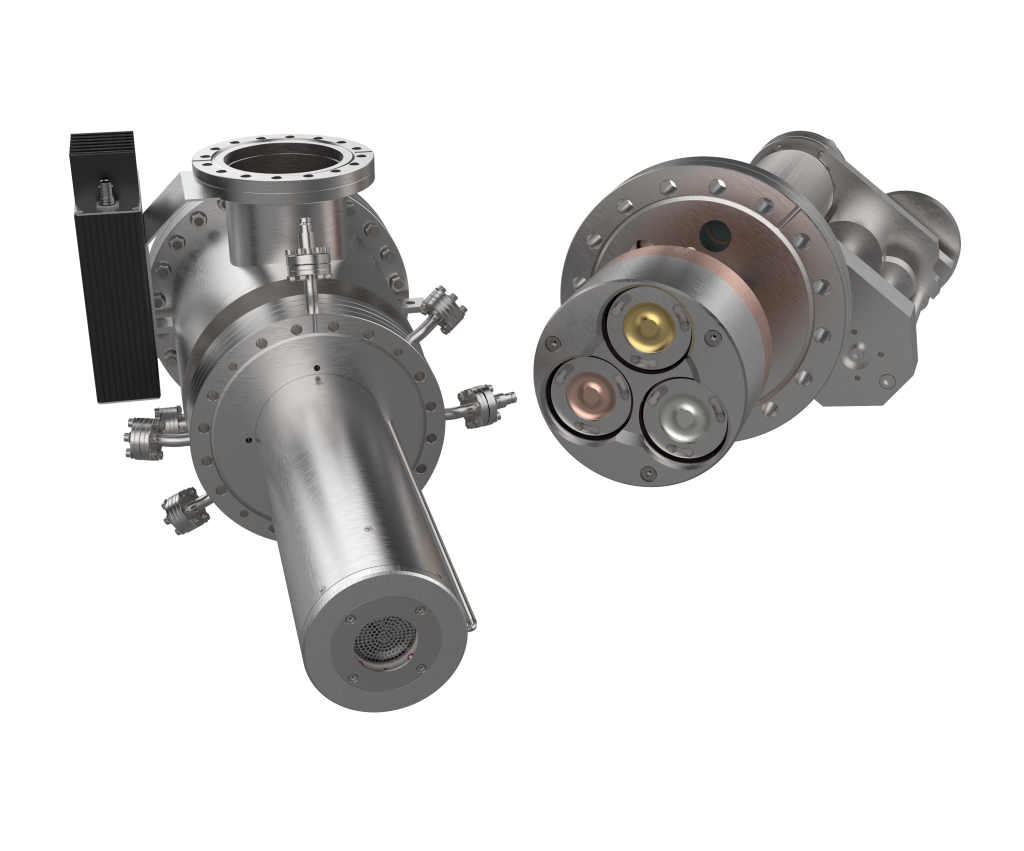

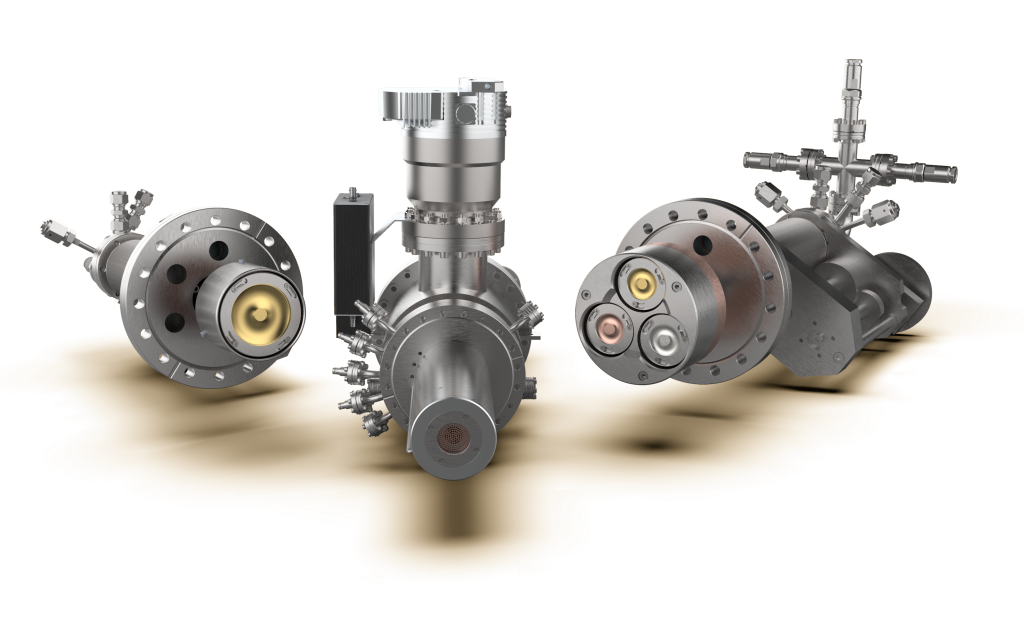

Nikalyte has developed NL50, a novel, state-of-the-art nanoparticle deposition vacuum chamber to deposit bare spherical gold nanoparticles directly on a wide range of custom substrates. NL50 offers real-time control over the size and density of nanoparticles. A single layer of porous nanospheres can be deposited within 30 minutes. One can choose any substrate such as glass, plastic, or filter paper.

Contact our team today if you would like to know more about NL50.

References:

- Li et al. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 29, 651–655 (2014). https://doi.org/10.1007/s11595-014-0973-9

- A. Bansal et al. Nanoscale Advances 2, 3764 (2020). https://doi.org/10.1039/D0NA00472C

- Rahimi, and M. Doostmohammadi, “Nanoparticle Synthesis, Applications, and Toxicity”, in Applications of Nanobiotechnology. London, United Kingdom: IntechOpen, (2019). https://www.intechopen.com/chapters/69099 DOI: 10.5772/intechopen.87973

- M. H. Hussain et al. Nanoscale Res Lett 15, 140 (2020). https://doi.org/10.11