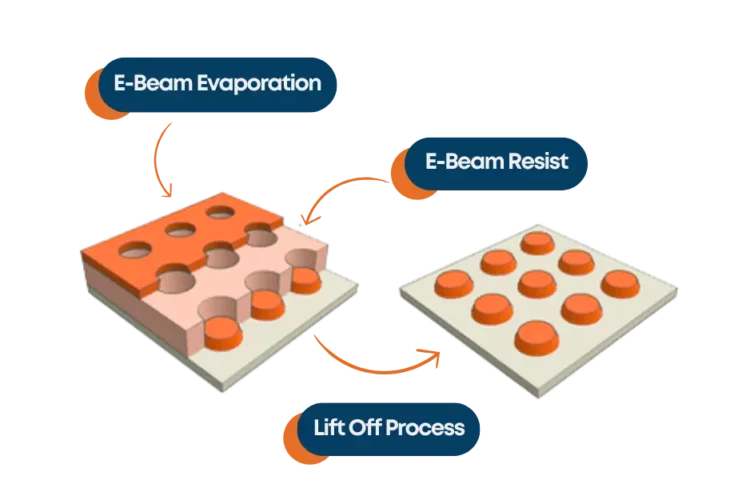

Lift-Off Process for Nanoscale Devices Using E-Beam Deposition

Image courtesy: Lift off process using E-beam deposition (adapted from Eschimese, D., Vaurette, F., Troadec, D., Leveque, G., Melin, T., and Arscott, S., “Size and shape control of a variety of metallic nanostructures using tilted, rotating evaporation and lithographic lift-off techniques,” Scientific Reports, 9, 14058, 2019, DOI: https://www.nature.com/articles/s41598-019-44074-w The lift-off process is one of the […]

Lift-Off Process for Nanoscale Devices Using E-Beam Deposition Read More »