Industry: Electronics / Semiconductor Packaging / Advanced Materials

Challenge:

Loughborough University, led by Prof. Changqing Liu, sought to address the growing demand for advanced interconnect materials in electronics packaging. Specifically, there was a need for low-temperature, fast bonding solutions that could withstand high temperatures and high-power density environments, such as those used in wide bandgap semiconductors and power electronics.

The project aimed to create a rapid, low-temperature bonding method using nano-silver (nano-Ag) coatings to form Ag-Ag direct bonds. These bonds would serve as a high-performance interconnect in high-power, high-temperature applications, providing both thermal and electrical conductivity.

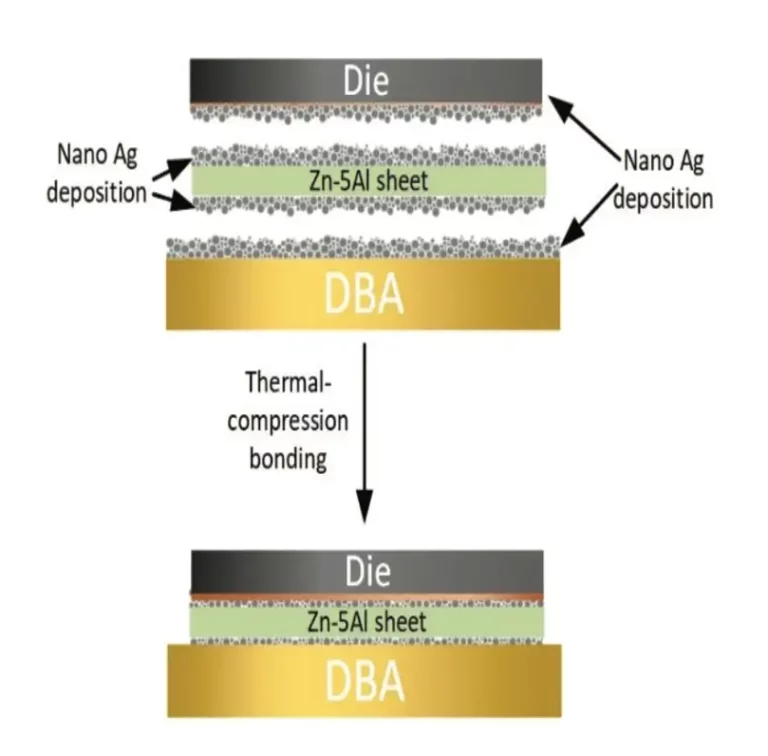

Image Description: Die-attach structure bonded using a nano-silver coating for enhanced electrical and thermal conductivity.

Solution:

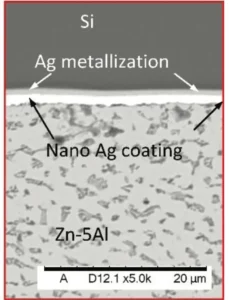

Nikalyte’s NL50 technology was used to deposit nano-silver particles (AgNPs) onto Zn-Al alloy sheets and Si die to facilitate direct bonding under low-temperature conditions. The nano-Ag coating enabled Ag-Ag direct bonding at 200°C, significantly improving the speed and efficiency of the bonding process.

The development leveraged the nano-silver coating for bonding under inert or vacuum conditions, resulting in a rapid, low-temperature bonding process with minimal silver usage, offering a more cost-effective solution compared to conventional methods like nano-Ag sintering.

Image Description: SEM image shows a die-attach structure with a nano-silver coating, enhancing electrical and thermal conductivity.

Results:

The nano-Ag coating technology proved highly successful in creating strong, durable interconnections for high-power density electronics. Key results included:

- Ag-Ag direct bonding was achieved at 200°C, far lower than conventional methods, which require temperatures above 300°C.

- The nano-Ag coating demonstrated a significant reduction in the amount of silver used, providing both cost savings and sustainability advantages.

- The bonding process showed improved efficiency, significantly speeding up production times compared to traditional methods like Ag sintering.

Conclusion:

This research demonstrated that nano-Ag coatings offer a promising solution for low-temperature, rapid bonding in electronics packaging. The results showed that nano-Ag direct bonding is a viable alternative for high-temperature, high-power density applications, and it can be integrated with wide bandgap semiconductors for efficient electronics packaging.

The new bonding method is also more sustainable and cost-effective due to minimized silver usage, presenting a significant improvement over conventional techniques. Further research and collaboration with Loughborough University are ongoing to enhance the scalability and application of this technology for industrial use.

Note: Full details of the project and results can be found in the publication here

Looking for advanced, cost-effective bonding solutions for your high-power electronics?

Contact us today to discover how Nikalyte’s nano-silver coating technology can help streamline your packaging process