Core-shell particles have gained significant interest in the scientific community due to their unique properties and diverse applications. With tailored stability composition and core-shell particle structure, scientists can explore new realms in areas like green hydrogen catalysis, biomedicine, and materials science. This blog post dives into the world of particle production, focusing on the production of core-shell structures, specifically using ultra-high vacuum (UHV) deposition via magnetron sputtering.

What are Core-Shell Particles?

Core-shell particles comprise a core material, typically a metal or metal oxide, surrounded by a shell material such as a polymer, silica, or another metal or metal oxide. This unique structure offers enhanced properties like stability, biocompatibility, and catalytic activity. With various nanostructured core-shell particles, researchers can achieve improved magnetic, optical, and surface properties.

What are the Applications of Core-Shell Particles?

- Drug delivery and bioimaging in biomedicine

- Catalysts for chemical reactions in catalysis

- Improved energy conversion and storage in solar cells, batteries, and fuel cells

The Core-Shell Particle Production Process

UHV deposition via magnetron sputtering is a widely used method for producing core-shell structured particles1. This technique allows for precise control over particle size, morphology, and composition. It also ensures a highly uniform coating, which is crucial for applications like passive daytime radiative cooling using hollow core-shell particle-containing coatings2.

Producing core-shell composite particles using magnetron sputtering involves several steps:

- Selecting appropriate core and shell materials based on desired properties and applications.

- Preparing the target materials and the substrate for the sputtering process.

- Generate a vapor of core and shell materials simultaneously using a sputtering process under high pressure UHV conditions.

- Vary the ratio of the sputter powers of the target materials and other sputter process parameters to select which material forms the core and which forms the shell.

The formation of core shell nanoparticles in the vapour phase enables the generation of structures that are not accessible by chemical synthesis. The synthesis of nanosized gold-silica core-shell particles and core-shell particle columns can also be achieved using this method. UHV deposition via magnetron sputtering has proven to be an effective method for producing core-shell particles alloy, core-shell particles emulsion polymerization, and even hybrid core-shell particles for mRNA systemic delivery.

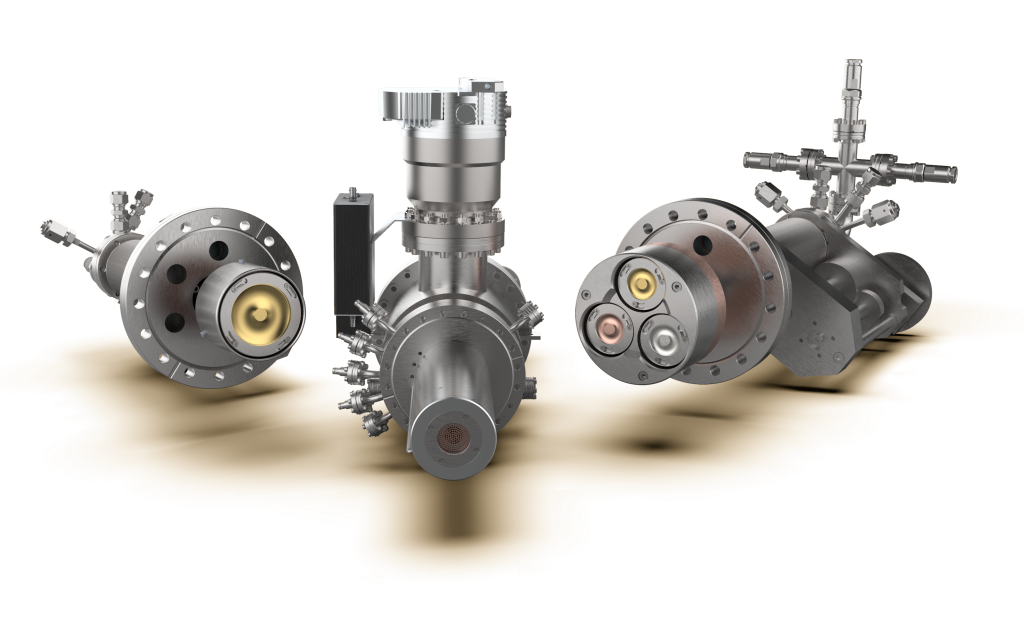

Nikalyte NL-UHV: The Ideal Solution for Core-Shell Production

The Nikalyte NL-UHV system offers a state-of-the-art solution for producing high-quality core-shell particles. With advanced magnetron sputtering capabilities, the NL-UHV provides precise control over particle size, morphology, and composition, ensuring uniform coatings and optimized particle properties. The system also offers excellent compatibility with various core and shell materials, allowing researchers to explore a wide range of core-shell particle structures and applications.

Looking for Core-Shell Production Solutions?

At Nikalyte, we understand the significance of core-shell technology in advancing scientific research and industrial applications. Our NL-UHV system is designed to provide unparalleled control over core-shell particle production, ensuring the highest quality particles for your research needs. With expertise in fields like nanotechnology, materials science, and green hydrogen catalysis, we strive to lead the way in renewing high-performance liquid chromatography with core-shell particles.

Contact us today to learn more about how the Nikalyte NL-UHV can help you revolutionize your research with core-shell particles.

References and further reading

- One-Step Growth of Core–Shell (PtPd)@Pt and (PtPd)@Pd Nanoparticles in the Gas Phase. Diana Nelli, Anjana Krishnadas, Riccardo Ferrando, and Chloé Minnai. The Journal of Physical Chemistry. C 2020 124 (26), 14338-14349. DOI: 10.1021/acs.jpcc.0c02621

- Dandan Hu, Shuai Sun, Peiyao Du, Xiaoquan Lu, Hui Zhang, Zhong Zhang, Hollow Core-Shell Particle-Containing Coating for Passive Daytime Radiative Cooling, Composites Part A: Applied Science and Manufacturing, Volume 158, 2022, 106949, ISSN 1359-835X