Surface enhanced Raman spectroscopy (SERS) and generic Raman spectroscopy are often discussed in tandem as they share many similarities. However, SERS diverges from conventional Raman imaging in various ways, making each technique applicable in different scenarios.

We discussed the working principles of SERS in our previous article How Does Surface Enhanced Raman Spectroscopy Work? This article will recap some of the main points of that article, but will primarily focus on what makes SERS unique to conventional Raman.

The Difference Between SERS and Raman Spectroscopy

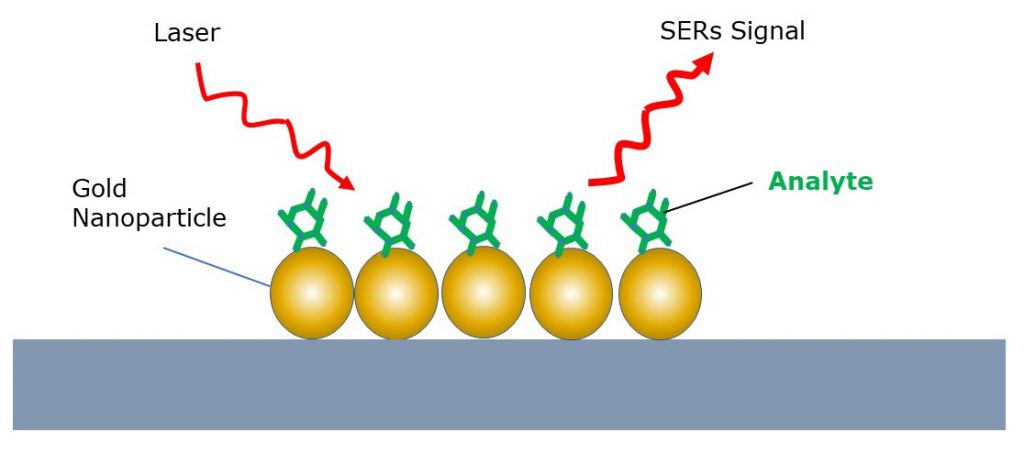

Raman spectroscopy is a chemical analysis technique used to identify a material’s chemical structure by observing how the chemical bonds interact with light in a material. SERS follows the same basic principles, with the express goal of increasing the Raman signal for better results.

When deciding which technique will be more effective for an application, one of the first points mentioned is that Raman might not be sensitive enough to carry out the required data acquisition and that SERS may be more suitable. However, there are more specific differences.

Raman Spectroscopy

There are two main problems with Raman spectroscopy. One is the insensitivity of Raman, and the other is that fluorescence emission interferes with the Raman, which reduces its signal. Raman spectroscopy is still a powerful method utilised to identify numerous chemical and biological species. It is a qualitative and quantitative method that can be used to identify drugs and pollutants and support the development of new medicine.

SERS

When working on a low concentration application, SERS is the preferred method because it is a powerful, highly sensitive technique that is also non-destructive. SERS enhances the Raman signal, which often cannot be identified with standard Raman spectroscopy. SERS operates at ppm and ppb levels, allowing for highly detailed analysis of material structures.

Nikalyte: Our SERS Technology

Nikalyte’s SERS technology was developed in-house as a flexible, low-cost technique with state-of-the-art sensitivity. Our vacuum nanoparticles are ultra-pure and are free from hydrocarbons and ligands, and our deposition technique allows for detecting analytes at a ppb level.

If you want to enhance your SERS research, Nikalyte’s NL50 equipment is the ideal solution. It is suitable for producing gold and silver materials and was developed with compactness and ease of use. The key features of theNL50 include:

- Flexibility

- Real-Time Control

- Ultra-Pure Nanoparticles

Flexibility

With the NL50, you can deposit on any substrate, making it suitable for various applications. The suitable substrates also include filter paper, glass and plastic.

Real-Time Control

The nanoparticle properties can be controlled in real-time. The density and size can easily be monitored and controlled using the NL50, and it is often used in nanoparticle SERS research and development.

Ultra-Pure Nanoparticles

Some nanoparticles are chemically synthesised, but Nikalyte’s are generated from 99.99% solid source material and are hydrocarbon and ligand-free and ultra-pure. Bare nanoparticles are preferred because they are more sensitive to analytes.

For more information on our NL50 or SERS applications, get in touch with Nikalyte today, and a member of our team will be happy to assist you.

If you would like to learn more, refer to our article on The Benefits of Surface-Enhanced Raman, or contact a member of the Nikalyte team today.