The transition to sustainable energy sources is a critical objective, and electrolyzer technology is at the forefront of this endeavor. A notable advancement is the utilization of nanoparticle coatings, which have shown substantial promise in elevating electrolysers’ efficiency and operational effectiveness. This article delves into integrating nanoparticle coatings within electrolyzer technology, spotlighting its potential to enhance hydrogen fuel cells, water electrolysis, and large-scale energy storage systems.

Electrolyzer Technology: Bridging to Green Energy

Electrolyzer technology is instrumental in fostering a green energy transition. Electrolyzers split water into hydrogen and oxygen through water electrolysis, central to hydrogen production. The hydrogen produced is pivotal for energy storage systems or immediate utilization in hydrogen fueling applications. This technology significantly reduces reliance on natural gas and fossil fuels, addressing the imperative issue of greenhouse gas emissions.

Unveiling the Potential of Nanoparticle Coatings

A significant stride in this domain is the incorporation of nanoparticle coatings. When applied to the electrodes of electrolyzer systems, these coatings markedly improve their performance. At the heart of this enhancement is the augmentation of surface area and modulation of surface energy, which fosters superior electrocatalytic activity.

Advancements in PEM Electrolyzers

In the realm of Proton Exchange Membrane (PEM) electrolyzers, the application of Platinum (Pt) coatings acts as an anti-corrosion measure to prevent oxidation. However, it can increase capital expenditure due to the cost of platinum[1]. Similarly, Gold (Au) nanoparticles have been employed to mitigate excessive passivation of the gas diffusion layer, reducing surface-contact resistance and energy losses[2].

Alkaline and Plasma Electrolytic Electrolyzers: A Novel Approach

Alkaline electrolyzers have also benefited from nanoparticle innovation, where the application of nickel nanoparticles has demonstrated an enhanced performance[3]. Furthermore, the addition of chromium (Cr) nanoparticles to a plasma electrolytic oxidation (PEO) electrolyte has broadened the range of coating compositions, improving the coatings’ properties[4].

Broader Implications in Electrocatalysis

Moreover, the domain of electrocatalysis has witnessed innovative applications of nanoparticle coatings, such as in the system composed of imidazolium-functionalized Mo3P nanoparticles coated with an anion-exchange ionomer for the electrocatalytic reduction of CO2 to propane[5]. Although not directly related to electrolyzer technology, it showcases nanoparticle coatings’ diverse applications and potential in electrocatalytic processes.

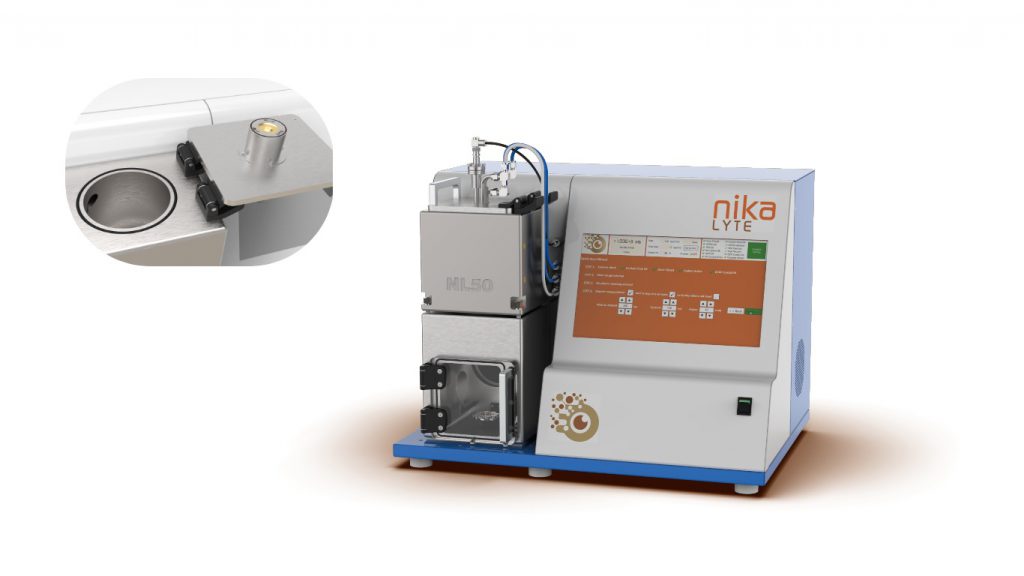

At Nikalyte, we envisage a future where the synergy between Nanoparticle Coatings and Electrolyzer Technology accelerates the global shift towards sustainable energy solutions. The potential to significantly augment the efficiency of hydrogen production and fuel cells is a scientific triumph and a beacon of hope in the battle against climate change. We invite you to explore the myriad possibilities this amalgamation offers as we stride towards a greener and more sustainable energy landscape.

References:

- Fan, Z., Yu, H., Jiang, G., Yao, D., Sun, S., Chi, J., Qin, B., & Shao, Z. (2022). Low precious metal loading porous transport layer coating and anode catalyst layer for proton exchange membrane water electrolysis. International Journal of Hydrogen Energy, 47(44), 18963-18971. https://doi.org/10.1016/j.ijhydene.2022.04.114.

- Liu, Y., Huang, S., Peng, S. et al. Novel Au nanoparticles-inlaid titanium paper for PEM water electrolysis with enhanced interfacial electrical conductivity. Int J Miner Metall Mater 29, 1090–1098 (2022). https://doi.org/10.1007/s12613-022-2452-1

- Bora, D. K., Bavdane, P. P., Dave, V., Sreenath, S., Sethia, G., Satpati, A. K., & Nagarale, R. K. (2022). Fabrication of Alkaline Electrolyzer Using Ni@MWCNT as an Effective Electrocatalyst and Composite Anion Exchange Membrane. ACS Omega, 7(18), 15467-15477. https://doi.org/10.1021/acsomega.2c00070.

- Lv W, Lu X, Chen Q, Ma J, Karpushenkov SA, Ignatenko OV, Wang F. Influence of Cr Nanoparticles on Plasma Electrolytic Oxidation Coatings on AM50 Mg Alloy. Coatings. 2023; 13(7):1196. https://doi.org/10.3390/coatings13071196

- Esmaeilirad, M., Jiang, Z., Harzandi, A.M. et al. Imidazolium-functionalized Mo3P nanoparticles with an ionomer coating for electrocatalytic reduction of CO2 to propane. Nat Energy 8, 891–900 (2023). https://doi.org/10.1038/s41560-023-01314-8