In the ever-evolving landscape of chemical engineering and materials science, the advent of coated nanoparticles as catalysts stands out as a beacon of innovation. This groundbreaking approach has the potential to significantly enhance the rates of catalytic reactions, a development with far-reaching implications in various industrial and scientific domains. This article delves into how coated nanoparticles can revolutionize catalytic processes, focusing on their mechanisms, applications, and future potential.

Understanding the Basics: Catalysis and Nanoparticles

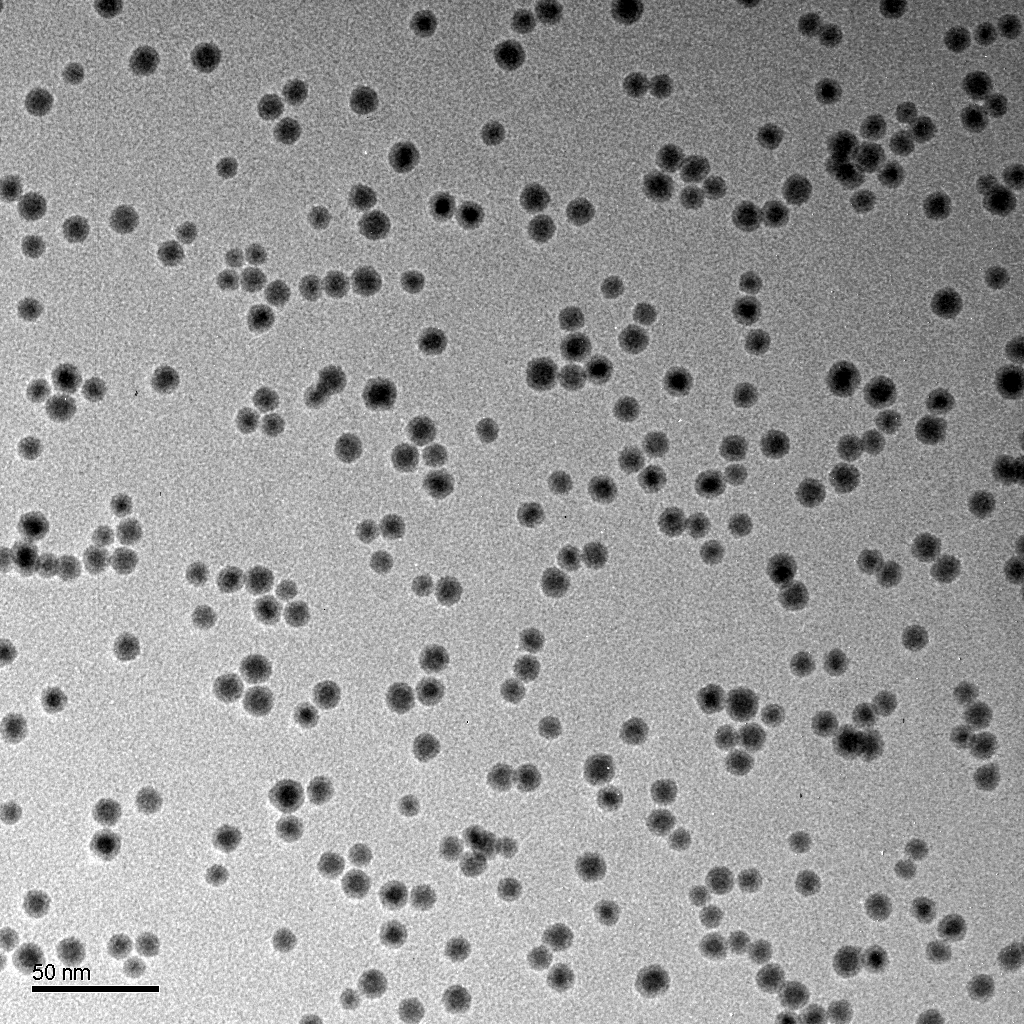

Catalysis is a fundamental process in chemical reactions, wherein a catalyst speeds up the reaction without undergoing any permanent chemical change itself. Traditional catalysts, while effective, often need more support in terms of reaction speed and specificity. Enter nanoparticles – particles between 1 and 100 nanometers in size. Due to their high surface-to-volume ratio, nanoparticles provide a larger active surface for catalytic reactions, thus potentially increasing the reaction rate.

The Impact of Coating on Nanoparticles

The application of a coating to these nanoparticles is a game-changer. This coating, usually composed of various metals or metal oxides, can dramatically alter the surface properties of the nanoparticles, leading to enhanced catalytic activity. The reasons for this enhancement are multifaceted:

- Increased Surface Area and Active Sites: Coatings can increase the effective surface area of nanoparticles, providing more sites for the reactants to interact with. This increase in active sites directly correlates with higher catalytic activity.

- Improved Selectivity: Coated nanoparticles can be engineered to be selective for specific reactants or reactions. This specificity is crucial in complex chemical syntheses, where unwanted side reactions can be costly and problematic.

- Enhanced Stability: Coatings can protect the core nanoparticle from environmental factors that might degrade its effectiveness. This stability is particularly important in harsh industrial environments.

Real-World Applications: From Pharmaceuticals to Environmental Science

The practical applications of coated nanoparticles in catalysis are vast and varied. In the pharmaceutical industry, they can catalyze the synthesis of complex drugs, increasing efficiency and reducing waste. In environmental science, coated nanoparticles are used in water treatment and air purification, where their selectivity and stability make them ideal for removing contaminants.

Challenges and Future Directions

Despite their promise, coated nanoparticles face several challenges. The synthesis of these particles requires precise control over size, shape, and coating composition. Additionally, concerns about nanoparticles’ environmental impact and potential toxicity remain an area of active research and regulation.

Embrace the Future of Nanoparticle Technology with Nikalyte

At Nikalyte, we are not just providers of nanoparticle technology; we are pioneers in the field, with over two decades of expertise in crafting state-of-the-art nanoparticle deposition equipment. Our innovative approach to nanoparticle technology, particularly in coated nanoparticles for catalysis, sets us apart as a leader in this dynamic industry.

Our products, including the NL50 and UHV equipment, are designed to cater to a broad spectrum of applications, offering unparalleled control over nanoparticle size and composition. Our unique vacuum deposition process ensures the production of ultra-pure, non-agglomerated nanoparticles, free from hydrocarbons and other contaminants that are often a challenge in chemical techniques.

We understand that each client has unique needs, and our extensive experience allows us to offer bespoke coating services. This customization is not just about meeting specifications; it’s about unlocking new possibilities in catalysis and beyond.

- Monodisperse and Non-Clumping: Our nanoparticles are uniform in size, enhancing consistency in catalytic reactions.

- Ultra-Pure and Crystalline: Purity is paramount in catalysis, and our nanoparticles are impurities-free.

- Hydrocarbon and Ligand-Free: This ensures that the nanoparticles remain unhampered in their catalytic activity.

- Consistent and Repeatable Results: Reliability is key in industrial processes, and our technology guarantees this consistency.

- Direct Deposition onto Target Substrates: This feature of our NL50 system provides ease and flexibility in application.

Are you ready to elevate your catalytic processes with cutting-edge technology? Discover how Nikalyte’s nanoparticle solutions can transform your business.